In Technical Grade

- With having good emulsifying and dispersing properties, lecithin can also be of great help in industry, improving products and optimizing work processes.

- In detergents and fabric softeners containing lecithin give textiles made of wool, cotton, synthetics and mixed fabrics a pleasantly soft and fluffy feel, even in hard water.

- In lubricants and hydraulic fluids, the plasticizing and dissolving properties of lecithin interact to regulate viscosity and flow behavior

- Lecithin used as a natural plasticizer, lecithin can partially replace synthetic primary plasticizers and synthetic extenders.

- In paints and lacquers, lecithins control the rheological properties, viscosity, flow properties and spreading ability. This applies both to solvent-based and water-based systems and to printing inks.

- Lecithin improves the flexibility of natural and synthetic-based adhesives and reduces viscosity. In many cases, lecithin also helps to improve adhesion.

- Lecithin ensures a high degree of explosiveness with simultaneously increased handling safety. This is due to the plasticizing and dispersing properties of the substance

- Leather care is one more technical application of lecithin. Here it is valued as a component of fatliquors.

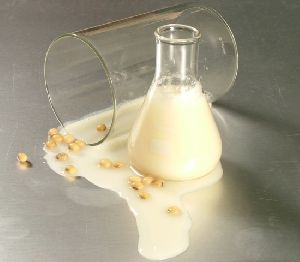

Hydrolysed Soya lecithin

Hydrolysed Soya Lecithin is an enzymatically modified complex mixture of phospholipids, glycolipids, glycerides and other minor components. It contains more of a hydrophilic portion, which imparts some useful, functional properties in food processing. Hydrolysed Soya Lecithin is produced by a special Enzymatic Hydrolysis of hydrated and Non-hydrated phosphatides.